You can power up to a 5.7 to 6 liter engine with this and an appropriate hydrogen generator setup like the FreeFuelSystem - not included - this is the hydrogen generator housing only. Picture is representative only. Must be mounted vertically as shown. Requires an inlet filter (fuel line filter works fine) not included.

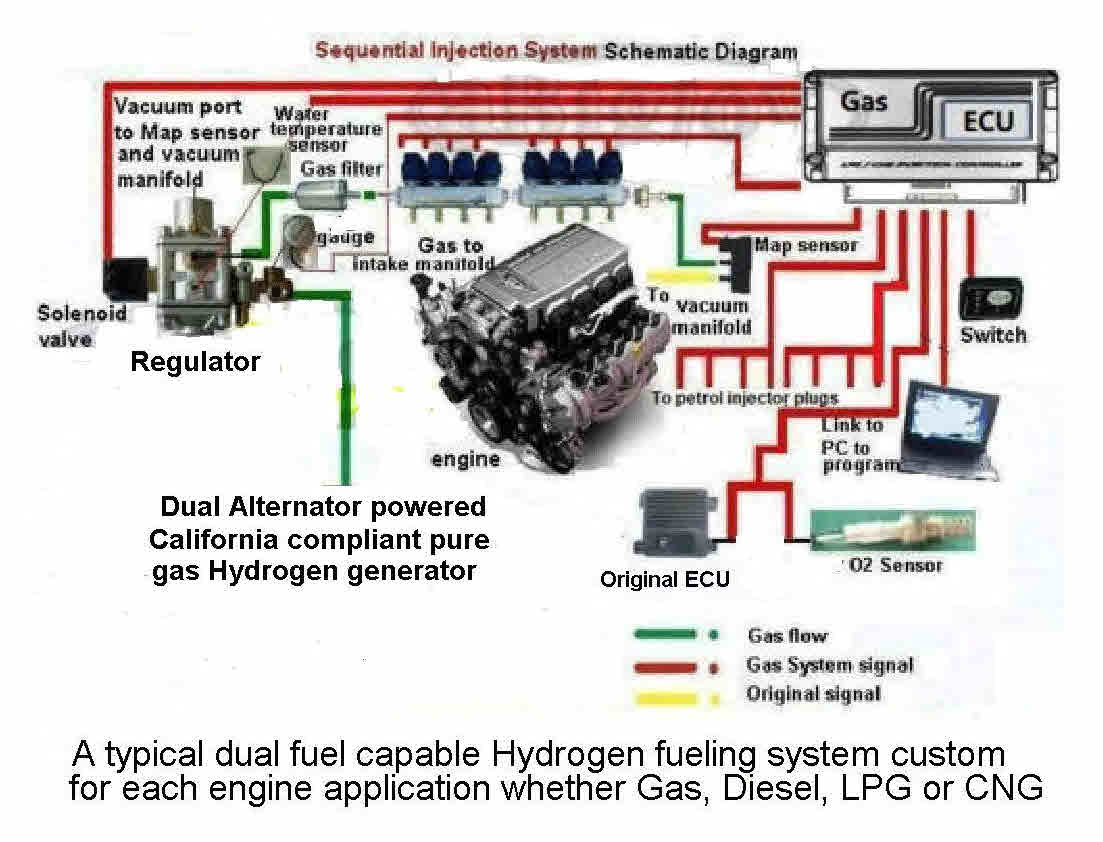

Connect the generator and components with quick connection tubing lines. A full system is a tank (like marine tank) a small rv pump (or you can use the windshield washer setup), a gaseous gas fuel injection system with piggyback ecm and a Hydrogen generator for this housing and buffer tank with odorant system, dual alternators and regulator. Not included. A pictorial diagram and minor instructions is included with where to source more part items.

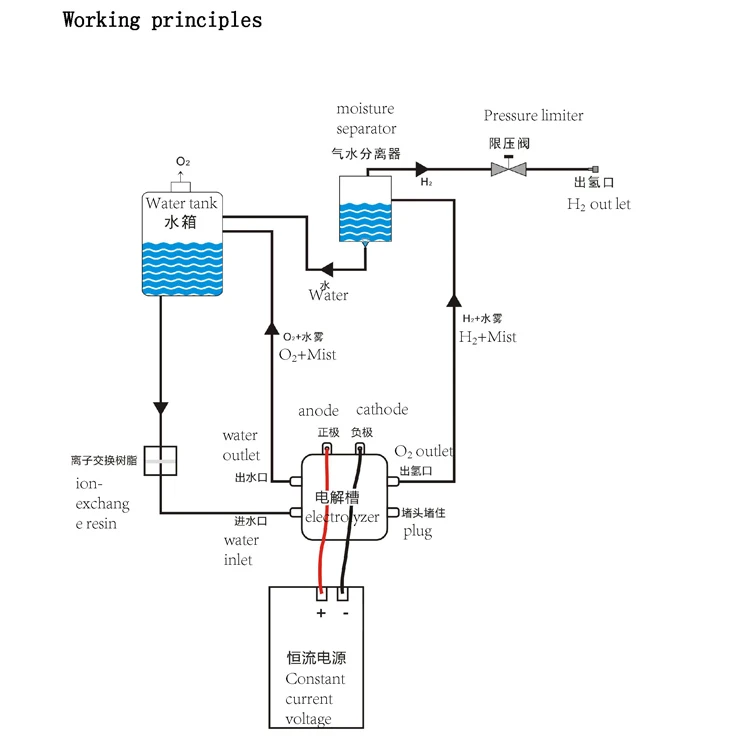

Here is the issue and weakness of most membrane pure gas generators, they need deionized water and are subject to freeze and clog, in addition to requiring lots of amps to operate because deionized water does not conduct electricity well thus they are of little use in general outdoors use. Our design for this housing can use a variety of liquid stock from urine to alcohol based antifreeze. As a wet generator, the anode side is constantly washing itself while in operation. There is a drain which can be set up to be filtered and recirculated.

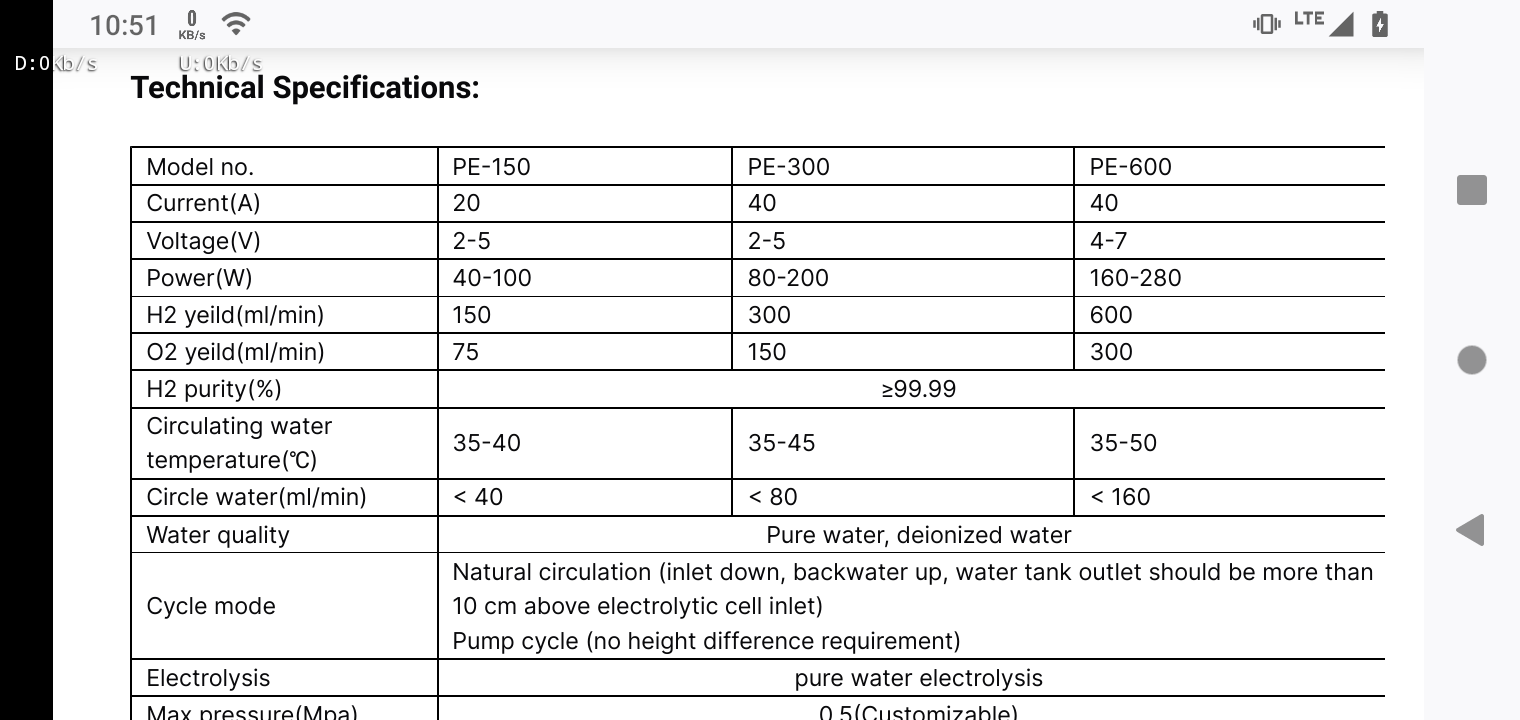

The pic which shows "Technical Specifications" is not related to this item but is technical normalities taken from the web that illustrate these issues. Notice to produce 600 ml per millimeters at 7 volts, 40 watts is consumed and generates 50 degrees centigrade "circulating". ( approximately 122 degrees F) Notice the more gas produced, the more volts and amps it takes as required.

If you want to beat high costs and inflation disconnect from commercial energy costs. Anywhere natural gas is a fuel, the FreeFuelSystem can usually replace it. This is a specially machined and modified and fitted housing for our wet membrane design hydrogen generator to self fill and handle gas production. It is required if you want to build a dual fuel hydrogen powering solution for engines. Meant for modern fuel injection engines. This is 15 inches tall and 8 inches in diameter. It pressurizes hydrogen and vents the oxygen as waste gas.

The question is not if hydrogen on the fly can power an engine, the question is where and how to mount all the components required to lawfully do so. This not HHO which is dangerous and lacks energy density to power an engine directly. Google search "Toyota Hydrogen Engine". For automobiles that is usually the trunk or rear area, for large trucks there is space on the frame rails, but underneath is not acceptable.

For instance to power a 5.7 to 6 liter engine with hydrogen, you would need approximately 0.85 to 1.7 kilograms of hydrogen per hour depending on the engine's efficiency and driving conditions; this translates to roughly 0.02 to 0.05 kilograms of hydrogen per kilometer traveled.

1 gallon of water = 3785.411 gms. The volume of 2 gm of hydrogen is 22.4 liters at STP. Hence, hydrogen produced = 420.60*22.4/2 = 4710.72 liters at STP.

At standard conditions, 1 liter of hydrogen weighs approximately 0.09 grams which means that to get 1 kilogram of hydrogen, you would need roughly 11,111 liters.

Therefore with sloppy math, 2 gallons of water yield about 9300 liters of hydrogen, or a little under 1 kilogram of hydrogen.

Therefore if roughly 0.02 to 0.05 kilograms of hydrogen per kilometer traveled is needed, one could use the windshield washer bottle tank to feed the hydrogen generator and drive at least 20 kilometers - using the high end figure - which is at least 12 miles on 2 gallons of water.

The question is how much, how fast, and how much pressure can the hydrogen generator produce and maintain??

Hydrogen production is a function of amps and electrode surface area, and pressure is design or compression of gas produced. For a PEM or AEM design it can produce directly 60 to 80 psi.

To produce 1 liter per minute of hydrogen, you would need approximately 500 watts of power, assuming a typical electrolysis system with around 50% efficiency; this translates to roughly 50 kWh of electricity per kilogram of hydrogen produced. That is around 5 amps DC continuous, so a dual alternator system will handle this easily. To a certain point, more amps will make gas faster.

Hydrogen generators get hot pushing lots of amps, which is why our systems are submerged flooded generators. Also they are not as susceptible to water impurities which result in precipitates.

For an engine dual alternators if a high Amp build are at a minimum required. Conceivably it could draw 30 amps continuous.

There are other factors involved such as a buffer tank, a second fuel injunction system and that is piggy backed on the vehicle ECM , and a special oxygen sensor setup.

Optional enhancements can include an EPA approved supercharger.

We are an EPA registered alternative fueling solution supplier and contract manufacturer. Home of the Freefuelsystem best suited for fleets and / or industrial equipment applications. Rather than sell, we license our systems because the EPA program requires it and it keeps us committed to making sure the product always works - and with our gas station program it effectively means a lifetime replacement warranty on critical parts. Hughes tool and die did this with the world famous rotary drill bit of the oil exploration industry. When it failed in drilling, they supplied another and took the old one for analysis, rebuilding, and improvements. This is one of the few items we outright sell.

The EPA final memo1a of 2020 allows this so long as the original oem system remains intact and not defeated, and emissions do not increase, which you may need to prove. You can Google search "2020_epa_anti_tamper_policy" to find it. To be clear, you cannot "convert" to Hydrogen you can only put on a "dual fuel" setup to switch completely to a side fueling system, or bi-fuel in a manner that does not increase emissions. You cannot tamper with or defeat the oem fueling system.

You can check on ebay for a 1000ml/min hydrogen generator - which is 1 liter per minute and it will cost you about $2,000 with taxes. The specs are typically

Product Name:High purity hydrogen generator

Output flow rate: HA1000 type 0-1000ml/min

Output pressure: 0-0.4Mpa

Hydrogen purity: 99.999%

Maximum power: 360w

That is typically an AC system macbine that is NOT a DC unit. Our is a direct DC system.

Our wet submerged pure gas generator can produce up to 2 liters per minute designed for this housing.

This is ONLY the modified housing to accept the hydrogen generator using 1/4 poly tubing quick connect. It has a float valve to be used with a fuel stock feed under low pressure and the housing is not meant to be pressurized. Meant to use a PEM or AEM flooded hydrogen generator design. The nice thing being, the hydrogen produced is 99% pure and the generator is easy swapped if it has issues, thus keeping the system functional and repairable by most competent persons

0.02 to 0.05 kilograms of hydrogen per kilometer traveled.

1 gallon of water = 3785.411 gms. The volume of 2 gm of hydrogen is 22.4 liters at STP. Hence, hydrogen produced = 420.60*22.4/2 = 4710.72 liters at STP.

At standard conditions, 1 liter of hydrogen weighs approximately 0.09 grams which means that to get 1 kilogram of hydrogen, you would need roughly 11,111 liters.

Therefore with sloppy math, 2 gallons of water yield about 9300 liters of hydrogen, or a little under 1 kilogram of hydrogen.

Therefore if roughly 0.02 to 0.05 kilograms of hydrogen per kilometer traveled is needed, one could use the windshield washer bottle tank to feed the hydrogen generator and drive at least 20 kilometers - using the high end figure - which is at least 12 miles on 2 gallons of water.

The question is how much, how fast, and how much pressure can the hydrogen generator produce and maintain??

Hydrogen production is a function of amps and electrode surface area, and pressure is design or compression of gas produced. For a PEM or AEM design it can produce directly 60 to 80 psi.

To produce 1 liter per minute of hydrogen, you would need approximately 500 watts of power, assuming a typical electrolysis system with around 50% efficiency; this translates to roughly 50 kWh of electricity per kilogram of hydrogen produced. That is around 5 amps DC continuous, so a dual alternator system will handle this easily. To a certain point, more amps will make gas faster.

Hydrogen generators get hot pushing lots of amps, which is why our systems are submerged flooded generators. Also they are not as susceptible to water impurities which result in precipitates.

For an engine dual alternators if a high Amp build are at a minimum required. Conceivably it could draw 30 amps continuous.

There are other factors involved such as a buffer tank, a second fuel injunction system and that is piggy backed on the vehicle ECM , and a special oxygen sensor setup.

Optional enhancements can include an EPA approved supercharger.

We are an EPA registered alternative fueling solution supplier and contract manufacturer. Home of the Freefuelsystem best suited for fleets and / or industrial equipment applications. Rather than sell, we license our systems because the EPA program requires it and it keeps us committed to making sure the product always works - and with our gas station program it effectively means a lifetime replacement warranty on critical parts. Hughes tool and die did this with the world famous rotary drill bit of the oil exploration industry. When it failed in drilling, they supplied another and took the old one for analysis, rebuilding, and improvements. This is one of the few items we outright sell.

The EPA final memo1a of 2020 allows this so long as the original oem system remains intact and not defeated, and emissions do not increase, which you may need to prove. You can Google search "2020_epa_anti_tamper_policy" to find it. To be clear, you cannot "convert" to Hydrogen you can only put on a "dual fuel" setup to switch completely to a side fueling system, or bi-fuel in a manner that does not increase emissions. You cannot tamper with or defeat the oem fueling system.

You can check on ebay for a 1000ml/min hydrogen generator - which is 1 liter per minute and it will cost you about $2,000 with taxes. The specs are typically

Product Name:High purity hydrogen generator

Output flow rate: HA1000 type 0-1000ml/min

Output pressure: 0-0.4Mpa

Hydrogen purity: 99.999%

Maximum power: 360w

That is typically an AC system macbine that is NOT a DC unit. Our is a direct DC system.

Our wet submerged pure gas generator can produce up to 2 liters per minute designed for this housing.

This is ONLY the modified housing to accept the hydrogen generator using 1/4 poly tubing quick connect. It has a float valve to be used with a fuel stock feed under low pressure and the housing is not meant to be pressurized. Meant to use a PEM or AEM flooded hydrogen generator design. The nice thing being, the hydrogen produced is 99% pure and the generator is easy swapped if it has issues, thus keeping the system functional and repairable by most competent persons

This is a custom part upon ordering is not refundable nor will be returnable.

This a la carte option does not include, tank, plumbing, gas generator design instructions, pump, hoses, or sensors - housing materials only - you need to have us design a full system for that above to be included.

UC_Image