The GM 6.5 PMD was meant to be cooled by fuel moving through the Injection Pump going back to the tank. There is a "Domino Problem" with the GM 6.5. It starts with the lift pump that really does not pump. The IP requires at least 6 psi to open the return valve so fuel can circulate, and thus provide cool fuel going past the PMD mounting platform to properly draw heat away from the power transistors on the bottom of the PMD. See the pic of the IP housing and large pool area where fuel fills on the way out the top through that little valve on the top of the IP. Custom Made Item Not Refunable or Returnable

No . . . there is no picture of the item . . . it is a square beefy extruded aluminum tank housing with a bolted on top and bottom and is further described below. See our terms of service. We also do not allow customers to post pictures of the item of review the items. The reason is that Google picks up all the images from websites and all over the web, indexes them and floods the web with the image giving competitors a way to copy the product - thanks but no thanks. You buy it - it works and that is where it stops, BUT you can refer people to our page to buy one also and you get an affiliate commission and that is all. No reviews or forum posts or descriptions etc. Frankly that is how the GM 6.5 Diesel is so misunderstood now - by forum sites which just want to keep providing another posting space for another ad to line theie pockets, and they could care less if the solution is at hand or not.

This is just the first in a series of things that "snow ball" into PMD failure. If there is insufficient fuel pressure - then the fuel solenoid at the rear of the Injection Pump - which is effectively the "throttle" to the IP is now forced to be held open because of insufficient fuel, instead of fuel pressure actually easily pushing it open - like it would on a properly working Injection Pump - even a mechanical one - to accomplish engine "idle". the problem is the fuel solenoid is NOT meant to be in a 100% duty cycle, and it thus draws lows of current to do so and heats up - and causes the PMD's power transistors to get very hot - as they act as"pulse modulated" DC switches. they overheat and begain to operate erratically - and in fact all the cooling the in the world is not meant to replace overworking them. Soon they fail - and the PMD thus causes the engine to shut off - or not start - or hiccup erratically while running.

Everyone misunderstands the PMD issue and the 6.5. If you have fuel - that is adequate fuel pressure to the IP - the PMD does not get hot. What causes the heat is IT trying to drive the fuel solenoid more "open" than it needs to be because of low fuel pressures and volume the engine needs at the moment. A properly fed (fuel and PRESSURE) DS-4 will "idle" on its own pressures, and will "push past the fuel solenoid plate without the fuel plate needing to be pulled open - thus the extra heat the PMD experiences and eventually fails on

The failures of the PMD are tied to weak lift pump PRESSURES - and that - and relocating it to a cooling plate with fins - is what also helps to kill the PMD. The worst thing is - you can hear the pump running - and it may well - and usually is - pumping nothing at all as the engine and IP spec calls for.

Most do not realize it, but the DS-4 will try to keep the engine running all the way down to "zero" psi as long as there is some fuel "volume" to compress. It will adjust the stepper motor to change timing and all kinds of nonsense backstop measures that must be employed the way the software in the ECM was written.

Those in the know who rebuild the IP's know the DS-4 IP is tearing itself up basically on 95% of the 6.5's out there running "dry" as to immersion lubrication when one has weak lift pump PRESSURES - it is the fuel pressure that also lubricates the IP itself. It is running dry because the owner - started by GM unfortunately - never learned to put on a "real" lift pump that actually makes the required pressure with good lubricating fuel oil the IP needs to have long life.

Rebuilding IP's so many have been seen with so many scuffed and scarred up internals - that will still keep working by the way - from low fuel pump pressures - and I know it feeds the whole IP rebuild business and all of those in it who rebuild IP's

The best place for the PMD on the 6.5 is actually on the side of the IP - when it is properly fueled with adequate fuel under PRESSURE that is circulating fuel that is also returning to the tank of more than 5 psi at idle and up to wide open throttle. (of course sadly it is also a terrible location when one needs to replace it)

We tested the heat of a relocated heatsink mounted PMD versus one on a properly pressurized and thus cooled the IP directly as factory stock and the IP mounted one won the heat dump battle hands down.

This remote mount requires about 8 x 6 x 6 inches to mount and runs fuel through it coming from the IP so it is "functionally indentical" to the liquid cooled OEM location, and has a sight window so you can see it it full of fuel and fual is moving through it. It can mount two PMD's one - for a spare.

You need to have our Sure cure Lift Pump Solution Kit before we will sell this you. That is because no matter what you "think", no other fuel pump available for the GM 6.5 will positively move the fuel under proper pressure through the IP and this cooling mount to keep the IP lubricated, fed with fuel under pressure, and recirculate it back to the tank to properly keep the GM 6.5 engine running properly as disegined by Stanadyne. YES - Stanadyne - NOT GM - because they designed the IP system - NOT GM. The 6.5 Stanadyne DS-4 Injection Pump requires 5 PSI at it AT ALL TIMES minimum - and up to 14 PSI to properly operate - wheterh at idle or Wide Open Throttle. The OEM life will NEVER, and has NEVER met this spec - and that is the problem with the GM 6.5 diesel actually.

Starts but immediately dies . . . won't accelerate strongly . . . fish-bites (hiccups and stumbles) when driving like it wants to die - and stumbles but keeps running . . . hard shifts gears . . . - driving and it cuts out but will start again . . . . hard to start in the morning - skip starts requiring a lot of cranking time . . . idling and just cuts off.. Chances are greater than not it is the lift pump which is causing your PMD to overeat and eventually DIE, and as to the lift pump it does not matter if you bought it literally YESTERDAY, but a weak lift pump has been know to blow a NEW PMD in less than a week !!

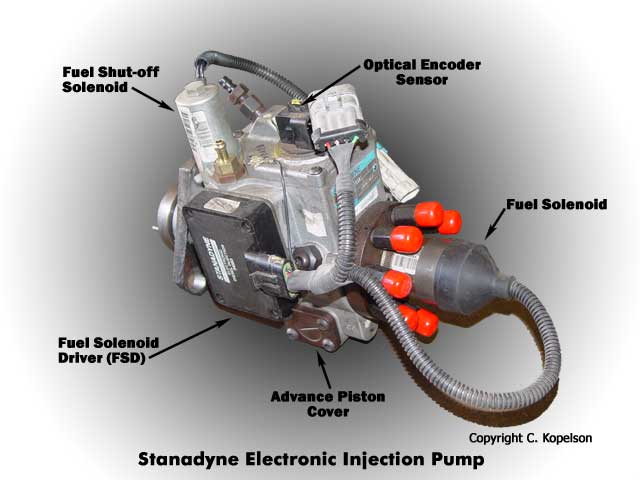

There is a LOT of misinformation about the causes of the failures of the 6.5 PMD - or "Pump Mounted Driver" - also called the Fuel Solenoid Driver [FSD] too.

It is always said that GM made a mistake mounting the PMD on the side of the Injection Pump, and it needs to be remote mounted on an aluminum cooler plate with fins to keep it from failing.

NOT TRUE. The truth is the Injection Pump (IP) has a perfect place (yes admittedly hard to get to) to mount the PMD - and IF the IP is keep under proper pressure of fuel above 5 psi which means the fuel is recirculating like it is supposed to - there is a large pool of fuel under the PMD that exits at the TOP of the IP and thus draws the heat from the PMD and that created by the IP operation and sends it back to the fuel tank where it is dumped into the fuel of the tank. This also serves the purpose of force lubrication under the fuel pressure to lubricate the IP itself thus also keeping the friction of the moving parts of the IP to a minimum

The REALITY and TRUTH is the real problem with the 6.5 is that the STOCK lift pump CANNOT and DOES NOT keep fuel pressure above 5 psi, and thus recirculating this fuel so - it causes damage to and eventual failure of the PMD by "blowing" the power transistors that you can see on the underside of the PMD - and at least five things simultaneously happen.

1. The IP does not run well without pressurized immersion lubrication, thus causing wear to the IP.

2. The first stage of the IP does not have enough fuel under pressure to send to the second stage for maximum compression to prepare to inject. This IP is self regulating and uses what it requires up to 14 psi to have adequate pop pressure for a good strong running diesel.

3. To compensate for the weak fuel pressure, (and this is worst part) the PCM finds itself commanding the fuel solenoid to hold itself "more open" in a higher "duty cycle" no different than like a fuel injector would - to let the maximum missing fuel through - and that is what CAUSES the transistors on the PMD to heat up - because they are in the circuit as high speed "switches" and if this overworking is not bad enough - if there is no way to dump the heat they create somewhere they will burn themselves up - and that will be the end of th PMD - and at the very least shorten the reliabie life time of the transistors themselves. This will overheat ALSO the fuel solenoid itself - when the system was designed for fuel pressure to partly hold it open - in essence the engine is designed to let itself "idle" and even accelerate somewhat by the increased fuel pressure at the fuel solenoid "plate".

When transistors are overworked like that their operating characteristics with them from there on "vary" - they may not FAIL immediately. but they will behave erratically to their specifications and this cannot be fixed ever. The transistors - if taken out - may well even "test" OK, but they will then forever behave erratically - and this will result in the 6.5's characteristic hiccups, stumbles, cut-outs, hard starting and many other symptoms of impending complete PMD failure. You can find evidence of this by viewing the middle contacts on the PMD cable - has "bluish" contacts - from high amperage flowing through. It should also be noted that you risk burning up the fuel solenoid itself with a weak lift pump and that is the major cause of many IP rebuilds. See also https://bigbay4bestbuys.com/Sure_Cure_GM_6_5_Lift_Pump_Solution_Kit for how to stop that.

4. Low fuel pressure means the Optical Sensor is also not immersed in fuel and in fact there may be "foaming fuel" in the sensor wheel which is read at the top of the IP just before the return valve, this may throw errors like

Diagnostic codes OBD I

DTC 17 - High Resolution Circuit Fault

DTC 18 - Pump Cam Reference Pulse Error

DTC 35 - Injection Pulse Width Error (Time Short)

DTC 36 - Injection Pulse Width Error (Time Long)

DTC 54 - PCM fuel circuit error

On OBD-II vehicles the code will have a "P", "P0" or "P1" or "P12" in front of it. A common one on OBD-II vehicles is the code P0251. This does not mean the Optical Sensor is absolutely bad needing replamcnment. See for instance https://www.yourmechanic.com/article/p0251-obd-ii-trouble-code-injection... The first place one should ALWAYS start is with the lift pump - and its PRESSURE - not just looking at fuel flow; and a clear fuel system without clogged fuel filters.

All of these are "Optical Sensor" codes and can be caused by "Dark Fuel", or "foaming fuel" as a result of weak fuel pressure also or your own fuel.

5. You will get poor performance or acceleration, assuming you are able to get it started to run at all.

What suffers and fails is the PMD, and there is nothing wrong with it other than the Power Tanssistors are damaged beyond operationality and / or reliability.

The PMD (pump mounted driver) is that small black box originally mounted on the side of the DS-4 Standyne injection pump. It is a signal amplifier that powers the fuel solenoid just like a fuel injector driver does in a gasoline engine ECM. It contains 2-250 watt capable transistors which create a lot of heat when worked HARD. Stanadyne designed this to be mounted on the side of of the DS-4 Injection Pump when there is supposed to always be a large cool pool of fuel oil flowing past there to draw the heat of of the transisteros.

It matters not that the DS-4 injection pump is mounted in the engine valley below the intake manifold so much as it is mandatory that a cool pool of fuel keep circulating to cool the IP and the PMD to take the heat back to the fuel tank where it is dilluted by a larger pool of fuel in the tank. As most people know, electronics do not do well under heat and they will fail prematurely. Symptoms of failure are stalling, hard starting, surging, poor fuel mileage, erratic idle/throttle and finally no-start. When they go it usually will not give any codes with the SES (Service Engine Soon) light.

So if you have a relocated PMD it is likely running hotter where it is than if it were on the side of a properly fueled under pressure, DS-4 IP, recirculaing fuel back to the tank . . . and anyway . . .

We can assure you that a PMD [FSD] on the side of a properly fueled under pressure in excess of 5 psi at all times IP whether at idle or under wide open throttle - will NOT fail, because the check engine light will show FIRST when fuel temperature reaches 195 degree F.

When a diode or a transistor fails, one of two things usually happens: A junction (or junctions) go short circuit (its resistance becomes very low or zero). A junction (or junctions) go open circuit (its resistance becomes very high or infinity).

Thermal overstress — a.k.a. "excess heat" — can and WILL cause semiconductors to fail. Excess heat melts materials, chars plastics, warps and breaks semiconductor dies, and causes other types of damage. In general, devices should not operate with a junction temperature above 125–150°C.

150°C is about 300°F - and under a hood that is easily reached. BUT . . . believe it or not with the PMD mounted on a properly fueled - as in proper fuel pressured DS-4 Injection Pump - even located where it is -- it does not get over 150°F - that is about 65°C - because the fuel is constantly recirculating and the Optical Sensor is also a Temperature Sensor and it would throw an "overheat" fuel code above 194°F - whichi about 94°C.

Semiconductor devices should operate within the range of voltage, current, and power limits established by the devices’ manufacturers. These limits exist for both power and I/O connections to a device. When a device operates outside this “safe operating area” (SOA), electrical overstress (EOS) can cause internal voltage breakdown that can, in turn, cause internal damage that ruins the device. If the EOS produces a higher current flow, the device can also overheat, adding thermal overstress to the causes of failure. The added thermal stress leads to a secondary-mode failure, named because the thermal stress arose from the primary EOS.

A PMD mounted on an aluminum plate with cooling fins - can easily get OVER that safe heat range especially if NOT in good AIR FLOW by just how it operates. Mild "Heat Soak" normally will not hurt a semiconductor - if sitting - and not powered, but using it as a switch - as it is in the PMD causes heat especially when the fuel solenoid is working it hard. So . . . they fail.

The worst thing you could actually do is mount the PMD on that cooler plate in the relocation kit - but anyway be that as it may be it works . . . the easiest way to repair one is replace the Power Transistors and the PMD will be good as new again - assuming nothing else is wrong with it.

VENDED BY BITCOIN PAYMENT ONLY

WHILE THE WEBSTORE WILL ACCEPT A BANKCARD PAYMENT WE RESERVE THE RIGHT, AND USUALLY WILL, REFUND THAT PAYMENT METHOD AS THIS ITEM IS GENERALLY VENDED BY BITCOIN PAYMENT ONLY

If you need info on how to buy with Bitcoin see => https://bigbay4bestbuys.com/bitcoin_climb

See also http://bigbay4bestbuys.com/Sure_Cure_GM_6_5_Lift_Pump_Solution_Kit

and see also

http://bigbay4bestbuys.com/6_5_lift_pump

Plumbs into the return fuel line from the IP to th tank - about 30 minute install job assuming you already have the PMD relocated

Contents:

1. Remote mount tank that can mount two PMD's that requires 8 x 6 x 6 inches spaces to mount upright with sight widow and optional fuel temperature probe

UC_Image