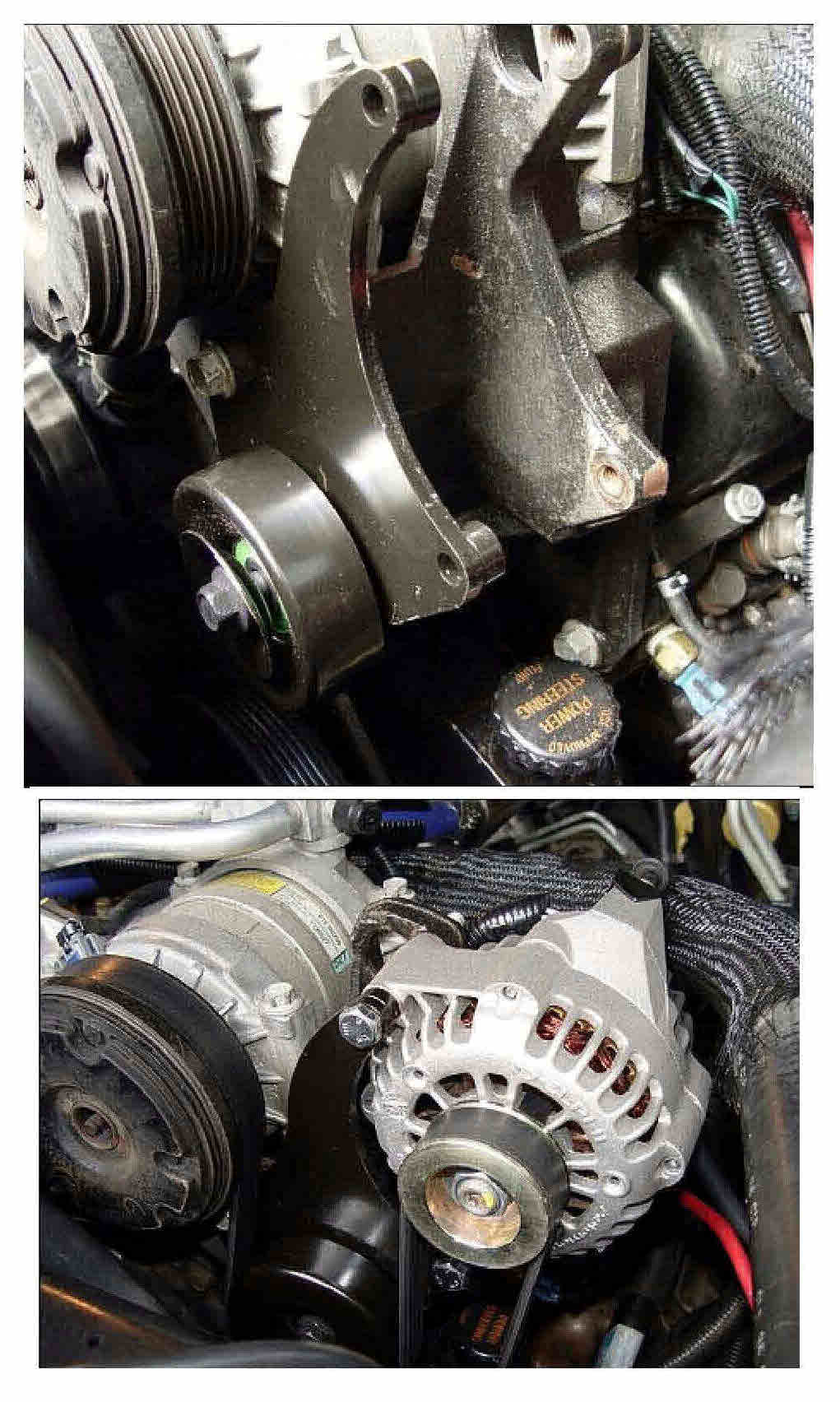

Dual alternator plate for GM V-8 and V-6 engines with this drivers side air conditioner mount serpentine belt. Actual plate picture not shown. Fits most 1999 to present. V-8 and V6 engines with the drivers side A/C pump mount. This version is for the vans or units with a remote Power Steering mount tank Check your engine to see if you have a steel engine lift ring similar as shown in the upper right (rear) of the picture except it will not have the two tapped holes as shown, but willhave a oval hole in a steel lift ring and is not cast. PLATE ONLY - (the black part in the front of the upper picture) you will need to source the idler pulley and other parts - a bone yard will do fine for the pulley and spare alternator often. A CS-144 alternator will also fit with the same mounting holes. GM wiring schematic diagram and parts list is included - including recommended belt size. No alternator mount hole spacers welded on - washers instead.

The difference betweeen upgrading an alternator to high output - like a 220 amp stator versus using two alternators is the output at low rpm and load on the alternator. An alternator under load gets hot, as does the voltage regulator. An internally regulated GM alternator with a 220 amp stator has a greater chance of blowing the voltage regulator and the rectifier - or at least one or two diodes in the rectifier - which is just as bad, - than using two even stock alternators. Diodes fail under heavy constant load - for example if an alternator is used for welding above 15 volts the diodes will fail unless they are non-avalanche style and high amp like 75 or 80 amp - which multiplied by three is a 240 amp pass capabilitiy. When a diode fails you will not get full output available from the alterntor and you may heard it emit a high pitched squeal, though it will still put out voltage and amperage, though at idle you may only get 13 to 13.5 volts max.

Thus a severly discharged battery or other load will hit the alternator for maximum output ability, and if it only had 40 amp diodes, the best it can pass is 120 amps before the diodes will avalanche to save themselves or fail to pass the full output when the stator field is at full strength. If you are using two alternators, the load on each is fifty percent less, and the voltage output instead of dropping may likely stay at its maximum like 14.1 or 14.2 with dual alternators. A single high amp alternator will drop to possibly around 12.6 to 13 volts depending on what else is loading the alternator, and then the battery is also suffering a discharge. that is why you need to rev the engine a bit if you are trying to give another person a jump start - to make the alternator put out more amps..

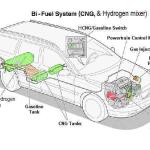

If you are running a constant heavy load like a good true gas hydrogen generator it will not take long before the regulator or rectifier blows, and people with high power aftermarket stereos experience the same thing.

The best of both worlds is to upgrade both alternators to be twins of each other to a high amp output, and be sure there is plenty if room for cool air to get to the alternator.. Two 240 amp stators with 80 amp non-avalanche diodes and proper size battery cable of 2 or 4 gauge may well put out OVER the rated combined 480 amps.

As an example if one is running a 40 amp capable 120 volt AC inverter, and a microwave that draws 10 amps AC (which is around 1000 amps DC) will load the two alternators to their max - and a single alternaor will not be able to keep up and will drop into discharing the battery and it will be getting really hot - but with two alternators even at idle a proper external industrial voltage regulator system will allow full field strength and if you have proper cabling to the inverter, and a voltage and amp gauge, you may see the voltage output remain at around 14.2, and amperage - which is a measure of amperage consumption actually - go to zero which means the inverter is consuming all that the alternators are putting out. You will feel even battery cable to the inverter getting warm passin all that current trought it to the feed the inverter. BUT if the voltage does not drop, then the batteries are not into a discharge scenario yet. the weak link of the GM system is the internal voltage regulator and that is why they have put cooling fins on the later model alternators and moved them outside the stator / rotor case. To solve the problem completely; use a commercial grade external voltage regulator.

When put on a test stand, a DR44G put out about 50 amps at idle and 14.2 volts (the DR44G has a 14.2 volt set point regulator) and when placed under simulated direct load it put out 140 amps at only 13.5 volts, and was getting warm fast.

On the VAN, only the 244 or 130 or 230 smaller size alternator will fit. This is because the alternator bracket fits it close to the engine to clear the steering column or engine housing well and the rear of the alternator of the CS-144 will bump the rear bracket. You can convert the CS-144's to 244 by simply changing them and putting on a new alternator plug. On the early van 1970 to 1995 if you have converted it to a serpetine belt, only the 130 or 230 family size will fit. You can upgrade a 230 family series alternator to 220 amps and high amp 80 amp rectifier, that actually will handle the load well and stay relatively cool enough, though use of a 244 series is a better option if it will fit. You can convert to a serpentine belt system by changing the accessories mount on both sides and the water pump and harmonic balancer pulley - as the three holes in the head where they mount - the location has not been changed since the introduction of the GM small block engine. See e.g. https://alternatorparts.com/ad244-series-high-output-alternator.html

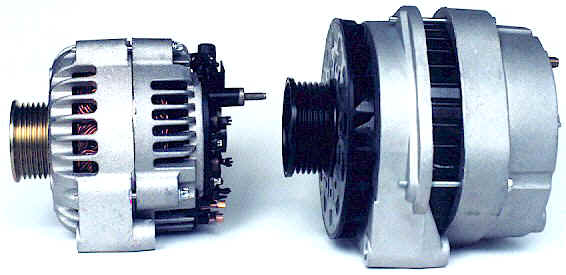

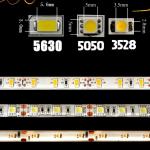

It is easy to tell a 144 and 244 series alternator because the stator shows in between the two case halves whereas on the 130 it ishows but is much smaller with an external fan though the stator does show and the 230 series is a smaller alternator and the stator does not show - the case halves fit together with each other. See the other two pics above.

CS130 had a max output of 105A at the end of its production and also seems to be the most common version of it.

CS144 was available in 108, 120 and 140A variations. It is hard to tell what it might be. it is best to just upgrade it to a 240 amp alternator which is easy on the 144 family using common tools. The 144 family disavantage is that it is a non open frame housing which pulls air poorly through from the rear, while the 244 series pushes air from the front to the rear, and has a "slotted" stlye open frame to allow generally better cooling.

The 144 family however can be upgraded by removing four bolts and splitting the housing, changing the rectifier, and put in new brushes, and a high amp stator and that is all. It is smart to put on smaller 2 inch pulley so it will put out at idle, and that is all. The 244 family must be pulled apart with a press or puller - or hammer on it by putting the nut on to "protect the threads" it if you are so unwise as to do so, and you must solder in a new stator.

The AD244 was available in 130 and 145A and HD 200 OEM configurations, and to look it up at the parts store just tell them 02-04 Cadillac Escalade 5.3L or 6.0L, or just about any gm pickup 99-04 4.8,5.3,6.0, 6.6 Duramax diesel and / or 8.1 The most commomn is the 145 amp version.

There is a 200 and 240 amp aftermarket stator available for the 144 and 244 - and the difference is the 144 is a bolt in stator with eyelets - and the 244 is a terminal-less solder in stator. You would need a high amp rectifier with 70 or 75 amp non-avalanche diodes for the maximum output available from the stators 75 amp rectifier diodes is what the GM HD OEM alternators also have, and Transpo make one with 70 or 80 amp avalanche diodes. Transpo makes a rectified with non-avalanche diodes for the 144 family but not the 244 family - so go figure.

This item is based on a replica with no alternator mount hole spacers welded on - use washers or a 1/2-13 plain nut instead. You will need space the diameter of the alternator you will use next to the power steering pump, as is there on most vans and vehicles with a v6 or v8 engine and you may need to gently bent the power steering line tubing to clear it. A hand held tubing bender from Harborfreight to bend it on the engine without removing the line. Uses the engine lift ring as a rear support point.. This is considered a custom order item and is not returnable. Custom Made Item Not Refundable or Returnable

This mounts the alternator just above the and to the side of the power steering pump. If you have a integrated power steering fluid tank with a cap order this one instead => https://bigbay4bestbuys.com/GM_V8_and_V6_dual_alt_plate_for_gas_engine

GM never made a factory dual alternator option fo the gas engine as far as is known, this is an aftermarket solution

You need dual alternators if you have a high amp stereo or to run any decent sized Hydrogen Generator system and the pump required to feed it at idle as a single alternator will not put out enough amps - even a high amp one

UC_Image

,

,

,

,  ,

,  ,

,  ,

,

,

,

,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,

,

,

,

,  ,

,  ,

,  ,

,