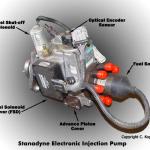

This a replacement or spare pump only

For 96 to 01 6.5 diesel vehicles. For pre 1996 6.5 diesel engines the lift pump mod is a requirement that routes through a relay and not the Oil Pressure Switch - often called "OPS". It is found many places on the internet like at https://www.dieselplace.com/threads/ops-relay-mod-install-1992-1995-obd…. The OPS can only tolerate 2.2 amps, so a relay was introduced in 1996.

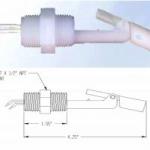

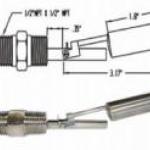

The kit needs and uses a 30 amp mini blade auto reset fuse breaker to replace the fuse under hood. This is because when the pump is new it may draw enough power to blow the 20 amp fuse, and a 30 amp solves it usually but a 30 amp auto reset breaker is better. Once the pump wears in and gets more loose, a 20 amp will not blow. green item in pic included. Finally, the bracket from a 4594 or 4070 pump kit is needed to mount the pump. NOT INCLUDED but needed. Those pumps however push only 4 to 7 psi and can and should only be used as an emergency spare. Even a P4601HP Carter which claims 9 to 13 psi, says in small print usually hard to find "nominal working pressure 6 psi". Don't pay $200 for a pump equally made in China and misleading you with performance it does not do. We tested one - and they do not put out that 9 - 13 psi atl all if for long. Plus quite as it is kept - they will not honor any warranty but for limited approved vehicles, and the 6.5 is not one of them.

The pump manufacturer boasts a 3 year warranty but it does not apply because we modify it to fit and be used and use it on the 6.5 diesel.

No matter what others have said and you see written on the web, having worked with a Stanadyne authorized certified rebuild AND repair shop, I can tell you the 5 psi figure everyone talks about is a MINIMUM number at idle or WOT REGULATED, as to how the rebuilds are tested for MINIMUM performance. No pump on the market for the 6.5 Diesel meets that but this one. Some guys are selling the Carter P4601HP, which as mentioned claims 9-13 psi, and once claimed 9 to 18 psi, are now made in China and do not do that pressure anymore, but it is NOT regulated and nor does it have a back check valve which allows for quick easy starts. there is one for sale here on ebay for $290 new - a smart person won't do that. And it has no back flow check valve.

The regulator that comes with this is a pressure plate design and is tricky to get set down to 20 psi but it can be done. Further the fuel filter can drop 5 to 7 psi depending on how clogged it might be. This system will push 20 psi at all times and it ends up at the IP from 18 to 13 psi at idle or WOT. The GM 6.5 you won't believe could have ever performed like it will with this lift pump solution.

These lift pumps are ideal for the DS4 because regulated a fuel gauge at 60-65 mph on flat would read about 12 psi. Lots of hills (up and down) and winding roads. Backing off the throttle for corners and down-hills, fuel pressure quickly goes back to 14-16 psi. At idle maintains about 17 psi. A new one might maintain 17 psi all the time. These pumps are capable of 30 psi so running them unregulated cannot be done. Over time they will get weak and or the the bearing bushings wear and a hard bump may open the circuit breaker. Turn off the key and immediately restart, but that means it is time for a new one. Another symptom is extended cranking especially if cold. A good owner who carries tools or mechanic can swap a new one in 30 minutes. That is why you always keep a new spare as these are not available locally. The emergency canister unit will only push around 7 psi so it is truly an emergency easy drive limp around option.

If you cannot feel the difference in a new pump, your 6.5 is not running right.

Starts but immediately dies . . . won't accelerate strongly . . . fish-bites (hiccups and stumbles) when driving like it wants to die - and stumbles but keeps running . . . hard shifts gears . . . - driving and it cuts out but will start again . . . . hard to start in the morning - skip starts requiring a lot of cranking time . . . idling and just cuts off.. Chances are greater than not it is the lift pump and it does not matter if you bought it literally YESTERDAY. Custom Kit Made Item Not Refundable or Returnable

The first thing it could be is if not the actual PMD itself, then it is an overheated power plug receptacle on the PMD connector plug that has lost its temper and will not hold a TIGHT firm electrical connection. It is the third connector from the end and you will see it because it will be the one that is usually bluish-green from being heated by resistance.

Yes it seems unbelievable, but it is true. HOWEVER, what contributes to this issue is low fuel pump pressure because the PMD is forced to pass lots of current so the fuel solenoid will be held open wider to let the engine idle. Eventually this will overheat the power transistors on the PMD and it will fail, and if you do not cure the initial problem the cycle will start all over again when you replace the PMD. Another thing that contributes is a PMD relocation kit not mounted in the properer place to actually keep the PMD cool with cool external air flow. That is first thing, and the second thing is to make sure you do is have 5 to 18 PSI at the injection pump.

A DB2 is not as sensitive, but a DS4 is destroying itself in several ways being run on low fuel pressure. It will usually keep the engine running - barely - all the way down to 1 psi, but what is going on is the PMD is compensating by holding the fuel solenoid "throttle plate" wider open to keep the engine running. This is straining the PMD and overheating both the Power Transistors on the PMD and the Fuel Solenoid located on the rear of the Injection Pump and one or the other is going to fail.

All solenoids are not meant to have 100% duty cycles because they are acting as electromagnets, and it takes a lot of current to do so, and the solenoid heats up in the process. Then they are both damaged and eventually they will both fail.- but usually the PMD goes first over and over again.

How can this be ?? . . . Because the DS4 like any Diesel fuel injection pump is designed to idle the engine using the internal pressure of the IP in a pressure balance and on the DS4 a spring loaded plate control throttle by gently pulling to assist the plate to open to accelerate the engine. That is why - for in a rebuild of the DS4 IP those experienced know setting the fuel solenoid is critical and a new spring is always best. In a rebuild more fuel solenoids are found "burnt up" than most any other thing damaged in the IP rebuild.

Another thing is . . .

Entrained Air and Vapor in Diesel Fuel Causes Retarded Injection Timing!

Air and vapor are compressible. Their presence in the injector delays the pressure buildup and the injection. The delay of the injection results in retarded injection timing. It sounds like a rod knock on a 6.5. Moreover, air in the fuel, no matter how small, remains a bubble. As a consequence, the amount of air entering the injector will vary from injection to injection. The more air/vapor present in the fuel the more retarded the injection timing, the less air/vapor present the less retarded the injection timing. It is also called "ignition delay" and is still the characteristic diesel rattle and knock. On the DS4, the IP itself is designed to send air to the top of the IP and force it out through the return valve. You need full inlet pressure for this to happen.

You can buy ONE AIr Dog system for typically $200 more and get ONE pump, or you can buy this and get a viewable regulated pressure system with THREE pumps with the one for a ready to go spare and one for an emergency use.

All of this surrounds ONE THING - low inlet fuel pressure. 5 psi is the MINIMUM but 18 is the "specified" maximum to let the DS4 IP operate properly - which includes then being thus your IP remains FULL of fuel under pressure to internally lubricate the IP and return air and fuel to the tank which acts as the cooling mechanism to keep the factory Pump Mounted Driver (PMD) cool.

So relocating the PMD is really just a band aid on the real issue - which is low fuel pressure - otherwise the recirculating fuel would keep the PMD cool on the side of the IP and it would not likely fail.. Of course the other issue is it is really hard to reach and change where it is mounted from the factory if it does fail.

This kit is an upgrade of the lift pump to a fuel cooled rotary vane lift pump that is regulated to 18 PSI. It has two pumps included - and one for an emergency replacement. It uses quick connect plugs so you can go back to an OEM pump at anytime. The nice thing about this kit is though you can barely hear it running, you can pop underneath and see what the pre-filter fuel pressure is with the engine running.

This is NOT a Carter P4601HP which many guys used for years - but now those are made in China, and Carter changed the specs at opticatonline to be 6 to 9 psi. (See https://carter.opticatonline.com/part/bcqs-0-carter-p4601hp ) We ordered one - and what showed up was a pump with what appeared to be 1/4 NPT inlet and outlet with 3/8 NPT barb fittings and it had absolutely no markings on the pump itself, and said clearly on the label which had been covered up with another label "Made in China". Made in China is not always a bad thing - but in this case for that money Carter charges and lower performance pressure we sent it back UNOPENED.

You will find reviews on he web saying the P4601HP is a good pump and it used to be - BUT NO MORE.

No . . . there is no picture of the item . . . it is described below. See our terms of service.

The lift pump on the 6.5 GM Diesel and any other vehicle that uses this kind of lift pump has a defective designed pump on it. It is NOT an electric fuel pump - it is an electrically energized mechanical fuel pump driven by SPRING pressure. Yes SPRING pressure and it is not even an electric fuel pump - meaning it does not pump fuel by electric means or a motor.

On the GM 6.5 - weak fuel pressure is literally a catastrophe waiting to happen. Low fuel pressure means the Injection pump is not full of fuel under pressure lubricating the internals of the IP properly and recirculating the fuel to the tank to help cool the IP and the PMD - if it still attached to it - and it is causing an over-working of the fuel solenoid as a "throttle mechanism", which in turn strains the PMD that powers the fuel solenoid, and the first to go will be the PMD, and then you are dead in the water or changing - or swapping out - a PMD if it is remote mounted. But what you probably do not really notice - is how sluggish the engine responds and it seems to have no power. But . . . hey . . . it is a diesel and is supposed to run that way you think!!! Wrong . . . weak fuel pressure and low lubricity fuel is slowly killing your IP!!!

This kit includes TWO Rotary Vane wet motor pumps, (one for a spare) and an emergency 4 to 6 psi unit, and the adapters required to install this on an unmodified GM 6.5 Diesel engine equipped vehicle. It creates a "functionally identical" lift pump like GM intended and spec'ed for the engine - but failed at because they used a solenoid type lift pump. For why GM failed see https://bigbay4bestbuys.com/6_5_lift_pump Ford and Dodge "knew better" and always used the Rotary Vane positive electric motor driven type fuel pump.

Most people do not know it - but the GM lift pump is THE SINGLE MOST AFFECTING ISSUE of the GM 6.5 diesel. GM never figured it out and would not listen to Stanadyne who tried to tell them the DS-4 Injection MUST HAVE 5 PSI or BETTER (up to 14 psi) at it at ALL TIMES whether at idle or wide open throttle for the injection pump system and engine to operate properly. There is no fudge room on this - it MUST HAVE 5 PSI. They were trying to tell them to STOP using that solenoid lift pump. Ford and Dodge have used this kind of positive displacement wet rotary vane pump for years. Only GM used that junk deign buzz solenoid pump. It only "pushes" as much fuel as the pressure of the spring in it behind the plunger puts forth.

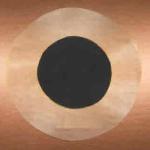

For those who do not believe - they have never seen the DS-4 Injection Pump being run on a test stand being run when the pressure drops below that 5 PSI mandatory threshold.. All kinds of "wonky" things begin to happen like timing changing dramatically etc Additionally - the major issue everyone has "band-aided" with a relocation heat sink - is the PMD issue where they think re-locating the PMD OFF the side to fhe DS-4 is a benefit - when it is NOT. The DS-4 has a big "POOL" of fuel right under the PMD which is supposed to be constantly recirculating back to the tank to act as a cooling pond-pool as a radiator for heat coming off the PMD and it works very well - IF AND ONLY IF - the DS-4 is kept full of fuel at 5 PSI or better at all times at idle or Wide Open Throttle (WOT) . The return valve on the top of the DS-4 opens at about 6 to 10 PSI to recirculate fuel and draw heat away. See the housing pic in the listing - and how big a pool of fuel would be under the PMD. (which mounts on the flat pad on the left)

None of this has EVER worked right with the solenoid pumps - because first - they cannot really hold pressure ABOVE 5 psi - one the get a "little" aged - or the spring gets immediately weak - and they cannot move enough fuel VOLUME and at the proper PRESSURE to effective do the cooling job. Hence the GM 6.5 has a been a real "witchy motor".

Quite a few things can affect an aggressive suction like this pump will produce. The biggest is the fuel tank sock as pictured. It has a trap door that will open if the fuel waxes - or the sock itself gets clogged with old algae or other debris - and this is not good if it enters this kind of pump as it will restrict the motor or even stall the motor - which uses the fuel to cool itself also.. For this reason the kit comes with a pre-pump filter.

This installs easily in about 10 minutes if you are a good mechanical person or about 30 minutes for the average person who has the right tools - and if it takes you more than an hour - you are drinking too many beers on the job.

Using the adapters it bolts in as a direct replacement - and the most that needs to be done is to drill new holes to clamp the pump slightly ahead of where the old one was mounted. All is included except two feet of common 3/8" fuel line hose. The second and third pump is a spare you should keep in your vehicle and the tools if you ever need it on the road for a quick swap.

The regulator has a small gauge that will allow you see how much pressure the pump is producing pre-filter. We recommend using - and you can also use a more accurate cab mount electric gauge found here => https://bigbay4bestbuys.com/round_digital_gauge and here => https://bigbay4bestbuys.com/hydrogen_purity_gauge (can also be used for pressure gauge)

Usually as all GM 6.5 drivers know - you can hear the pump running - but with this kit you can hear - if it is running "weak"; because you will not hear it running "strong" and unlike the solenoid pump - it sounds the same basically all the time - and may be pumping nothing really.

This item has been designed and reviewed in accordance California Air Resources Board (CARB) regulations and restrictions and because it is a FULL KIT that is a "functionally identical" replacement part system, it is an approved replacement part.for the GM 6.5 Diesel system for all engines from 1993 all the way to 2006. (Yes, they were made up to 2006 titled in some Motor home or specialty chassis vehicles like step vans etc - that sat in inventory sold and tilted into the 2006 model year by remanufacture vendors)

We guarantee this kit will end your 6.5 odd issues given everything else is proper and you are running good fuel.

The lift pumps hav e a lifetime warranty, but the manufacturer will not honor it because they do not specify this pump is to fit a GM 6.5 engine which is a slick and slipper term of their warranty The kicker is the pump is actually manufactured and sold also as a "universal pump" and it has NO APPLCATIONS listed at all. Often you can send an email with the words "warranty" and provide the specifications and they may warranty it - if it is completely dead - or you can prove it will not produce pressure. We will send proof of new purchase status as an original invoice needed for the warranty use if needed later. It is sad day for the GM 6.5 lift pump - as while the specs call for a 10 to 14 psi pressure - and the IP will take up to 18 spec - and a little over in reality, NO PUMP manufactured today as a replacement will meet that - but this one.

This kit produces a functionally identical part as identified at 13 CCR § 1900(20). [California Code of Regulations] and is thus exempt under any California Air Resources Board (CARB) regulation or jurisdiction.

When installed as instructed, this kit produces a "functionally identical" part to in minimum - but not limited to - the following pumps:

ACDELCO EP158 {#25115224} GM Original Equipment, DELPHI FD0009, CARTER P74001, AIRTEX E3158, AUTOBEST F2169, PRECISE 402P3158, SPECTRA SP1159 {#25115224, EP7288}, AND THE ACDELCO EP309 {#25117340} GM Original Equipment, DELPHI FD0031, DELPHI HFP921, AIRTEX E3309, CARTER P74143, PRECISE 402P3309, AUTOBEST F2310, SPECTRA SP1127, AND THE ACDELCO EP1000 {#15754298} GM Original Equipment, DELPHI HFP922, CARTER P74222, AIRTEX E3540, AUTOBEST F2551, TYC 152045, PRECISE 402P3540, AND THE SPECTRA SP1133 and as all "replacement parts" being sold in the marketplace for the 1993 to 2006 GM 6.5 L Diesel Engine this kit is "functionally identical" it can be sold without any CARB Executive Order of Exemption;

Unlike other pumps on the market - this one will hold pressure against the IP when you shut it off for quicker restarts

This item is NOT RETURNABLE, and no warranty applies beyond any required by law IF and ONLY IF it does not operate on arrival. Any claim must be made within 72 hours of delivery.

If you buy with Bitcoin shipping is FREE - that is we will refund the shipping and ship by Priority Mail to Domestic US, and for overseas buyers - we will deduct the amount paid from Priority Mail International of the Domestic US shipping cost.

If you need info on how to buy with Bitcoin see => https://bigbay4bestbuys.com/bitcoin_climb

UC_Image

,

,  ,

,

,

,

,

,  ,

,

,

,

,

,  ,

,  ,

,  ,

,

,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,  ,

,

,

,

,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,